Dieses Wiki ist ein Archiv bis 2023. Das aktuelle Wiki findet sich unter https://wiki.hamburg.ccc.de/

Difference between revisions of "Prusa i3 MK3S"

| Line 10: | Line 10: | ||

== Instructions for users of ''Microsoft Windows'' == | == Instructions for users of ''Microsoft Windows'' == | ||

| − | This is | + | This is what I did to get things going on a 64-bit laptop running ''Windows 10''. |

1. Download the latest version of the Slic3r (Prusa Edition) Software from GitHub: https://github.com/prusa3d/Slic3r/releases. (In case the link is dead, it's really important you look for the Prusa Edition, which is a fork of the original Slic3r software. Downloading and installing the non-Prusa edition of Slic3r means you won't get the hardware configuration file necessary to run the printer. As of today, GitHub hosts software for OSX, Linux, Windows (32-bit) and Windows (64-bit). | 1. Download the latest version of the Slic3r (Prusa Edition) Software from GitHub: https://github.com/prusa3d/Slic3r/releases. (In case the link is dead, it's really important you look for the Prusa Edition, which is a fork of the original Slic3r software. Downloading and installing the non-Prusa edition of Slic3r means you won't get the hardware configuration file necessary to run the printer. As of today, GitHub hosts software for OSX, Linux, Windows (32-bit) and Windows (64-bit). | ||

| Line 18: | Line 18: | ||

2. When installing the Slic3r Prusa Edition (PE) software, select "Original Prusa i3 MK3 with 0.4mm nozzle". Click next. Accept the two default things already check-marked and click Finish. | 2. When installing the Slic3r Prusa Edition (PE) software, select "Original Prusa i3 MK3 with 0.4mm nozzle". Click next. Accept the two default things already check-marked and click Finish. | ||

| − | 3. On the webpage where you are connected to the Octoprint Server, click on the wrench icon in the top right-hand corner. This will bring you to the settings page (HTTP:\\10.42.23.234/#settings_dialog). The OctoPrint Settings dialog window opens. From the left-hand side menu, under the heading FEATURES, click the API link (HTTP:\\10.42.23.234/#settings_api). Copy the API Key (6F9E5089D2BD4925A592E7A63E5874E4) | + | 3. On the webpage where you are connected to the Octoprint Server, click on the wrench icon in the top right-hand corner. This will bring you to the settings page (HTTP:\\10.42.23.234/#settings_dialog). The OctoPrint Settings dialog window opens. From the left-hand side menu, under the heading FEATURES, click the API link (HTTP:\\10.42.23.234/#settings_api). Copy the API Key, which is currently 6F9E5089D2BD4925A592E7A63E5874E4. Click Save (the blue floppy disk icon) and give it the name "Prusa Octoprint CCCHH" |

| + | |||

| + | 4. In the Slic3r software, click on the '''Printer Setting'''s tab. Select '''General''' from the left-hand menu. On the right-hand side, in the section labeled '''Printer Host upload''', type 10.42.23.234 in the '''Hostname, IP or URL''' textbox. Paste the API key into '''API Key / Password''' text box or | ||

| + | type 6F9E5089D2BD4925A592E7A63E5874E4 into the '''API Key / Password''' text box. | ||

| + | |||

| + | 5. Go to https://www.thingiverse.com/, find a thing and click '''Download files'''. You are looking for a file with an STL filename extension. For example, I needed a Japanese Go rice measuring cup to replace the one which came with my rice cooker. (https://www.thingiverse.com/thing:1282606) | ||

| + | |||

| + | 6. In the Slic3r software, click on the '''Plater''' tab. Select File, Open and navigate to the STL file you downloaded (or designed yourself). On the right-hand side, in the Print Settings, select either 0.15 OPTIMAL or 0.20 FAST. You only need the thinner settings for very fine, intricate details. Default fill density is 20%. 30% is a good balance between fast and strong/accurate. I heard you never want to print at 100% and that the absolute maximum should be 95%. Due to some physics magic, 95% is supposed to be stronger than 100%. (A real source for this information would be awesome.) | ||

| + | |||

| + | 7. In the '''Print Settings''' tab, select the Skirt and trim from the left-hand menu. The default for Loops (minimum) is set to 1. I was told to set this to 4 because this tells the 3D printer to print 4 quick loops around the object which is supposed to clean out the nozzle. (This is something akin to cleaning print heads before printing on an inkjet printer.) | ||

| + | |||

| + | 8. Back on the Plater tab, in the right middle section, select the Slice Now tab. Using the blue arrow levers (what are these), it's good to "play" the animation of printing of the 3D object, just to check that it looks ok. (How to judge this? Maybe someone reading this can add something here.) | ||

| + | |||

| + | 9. Click the Send to Printer tab. A window pops up titled "send G-code to printer host", add a checkmark to the Start Printing after upload box and then click OK. | ||

Revision as of 00:26, 12 November 2018

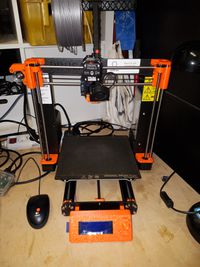

General Information

about our Prusa 3D printer. There is a Raspberry Pi connected to it, which is running the Octoprint Server. You can reach it by opening a browser and typing in the IP address 10.42.23.234 (HTTP:\\10.42.23.234). From here, you can click on the Control tab and watch the 3D printer printing via the webcam attached to it.

(NOTE: This will only work if you are logged into the club's WiFi. It will not work from home. It will not work if you are logged into FreiFunk's wifi connection.)

Instructions for users of Microsoft Windows

This is what I did to get things going on a 64-bit laptop running Windows 10.

1. Download the latest version of the Slic3r (Prusa Edition) Software from GitHub: https://github.com/prusa3d/Slic3r/releases. (In case the link is dead, it's really important you look for the Prusa Edition, which is a fork of the original Slic3r software. Downloading and installing the non-Prusa edition of Slic3r means you won't get the hardware configuration file necessary to run the printer. As of today, GitHub hosts software for OSX, Linux, Windows (32-bit) and Windows (64-bit).

(NOTE: To find out if you have a 32-bit or 64-bit Windows OS, type "Prozessorinformationen anzeigen" in the search box. You'll find the information you are looking for under the label Systemtyp.)

2. When installing the Slic3r Prusa Edition (PE) software, select "Original Prusa i3 MK3 with 0.4mm nozzle". Click next. Accept the two default things already check-marked and click Finish.

3. On the webpage where you are connected to the Octoprint Server, click on the wrench icon in the top right-hand corner. This will bring you to the settings page (HTTP:\\10.42.23.234/#settings_dialog). The OctoPrint Settings dialog window opens. From the left-hand side menu, under the heading FEATURES, click the API link (HTTP:\\10.42.23.234/#settings_api). Copy the API Key, which is currently 6F9E5089D2BD4925A592E7A63E5874E4. Click Save (the blue floppy disk icon) and give it the name "Prusa Octoprint CCCHH"

4. In the Slic3r software, click on the Printer Settings tab. Select General from the left-hand menu. On the right-hand side, in the section labeled Printer Host upload, type 10.42.23.234 in the Hostname, IP or URL textbox. Paste the API key into API Key / Password text box or type 6F9E5089D2BD4925A592E7A63E5874E4 into the API Key / Password text box.

5. Go to https://www.thingiverse.com/, find a thing and click Download files. You are looking for a file with an STL filename extension. For example, I needed a Japanese Go rice measuring cup to replace the one which came with my rice cooker. (https://www.thingiverse.com/thing:1282606)

6. In the Slic3r software, click on the Plater tab. Select File, Open and navigate to the STL file you downloaded (or designed yourself). On the right-hand side, in the Print Settings, select either 0.15 OPTIMAL or 0.20 FAST. You only need the thinner settings for very fine, intricate details. Default fill density is 20%. 30% is a good balance between fast and strong/accurate. I heard you never want to print at 100% and that the absolute maximum should be 95%. Due to some physics magic, 95% is supposed to be stronger than 100%. (A real source for this information would be awesome.)

7. In the Print Settings tab, select the Skirt and trim from the left-hand menu. The default for Loops (minimum) is set to 1. I was told to set this to 4 because this tells the 3D printer to print 4 quick loops around the object which is supposed to clean out the nozzle. (This is something akin to cleaning print heads before printing on an inkjet printer.)

8. Back on the Plater tab, in the right middle section, select the Slice Now tab. Using the blue arrow levers (what are these), it's good to "play" the animation of printing of the 3D object, just to check that it looks ok. (How to judge this? Maybe someone reading this can add something here.)

9. Click the Send to Printer tab. A window pops up titled "send G-code to printer host", add a checkmark to the Start Printing after upload box and then click OK.